Product Introduction

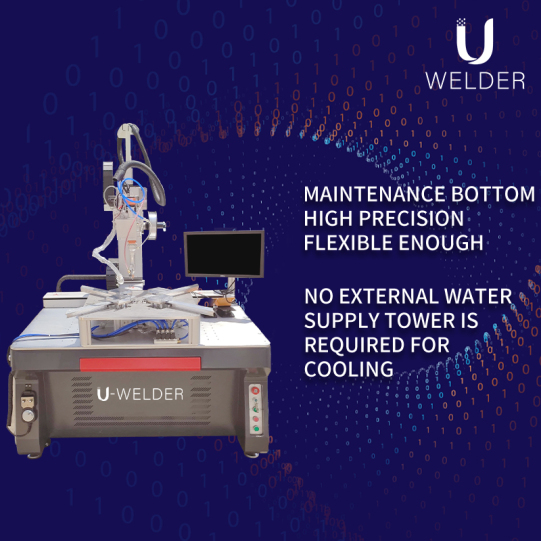

u-welder automatic laser welding machine can realize the welding of metal work pieces in straight lines, circles and other arbitrary trajectories, such as phone housing, mobile phone batteries, sensors, medical equipment and other industries. Laser welding machines use high-energy pulsed lasers to weld objects, laser pulses’ high energy and high density can make the welding smooth, the weld width is small and the heat-affected zone is small, and it can complete the precision welding that cannot be achieved by the traditional technology. Laser automatic welding machine series welding machine is a laser welding machine developed and produced with German welding machine technology.

The welding efficiency is high, the effect is good, and the operation is simple and convenient. It is suitable for the welding of flat straight lines, arcs and arbitrary trajectories of various materials. Applicable to all kinds of metal materials: aluminum, stainless steel, gold, silver, alloy, steel, diamond equivalent material welding or dissimilar material welding; applicable range: mobile phone batteries, jewelry, electronic components, sensors, clocks, precision machinery, communications , handicrafts and other industries.

u-welder automatic laser welding machine adopts manual design, simple and convenient installation and operation, adopts self-equipped cooling system, does not need any external water tower for water cooling, the maximum frequency can reach 100HZ, the linear speed can reach 8mm/s, which greatly improves the welding efficiency and welding quality. It can also be equipped with a four-dimensional ball screw table, using an imported servo control system, including a rotating table, which can weld cylindrical objects and other objects of various shapes, with a wide range of applications, high precision and fast speed. The current waveform can be adjusted arbitrarily, which can be applied to various materials and alloys.

Technical Parameters

| Main component name | Parameter |

| X axis effective stroke | 500mm |

| Y axis effective stroke | 300mm |

| Z axis effective stroke | 300mm |

| Dimensions | 1500×1400×1900mm |

| Machine weight | 280kg |

| Module operating speed | Y axis:10m/min |

| X axis:10m/min | |

| Z axis:5m/min | |

| repeated positioning accuracy | ±0.02mm |

| Rotating table | Circle runout accuracy ≤0.05mm |

| electricity demand | 220V/380V |

| Average load power | 7.5KW |

Configuration Parameter

| S/N | Name | Specifications & Models | QTY | Brand | Remark |

| 01 | Fixture mounting plate | 350mm×450mm | 1 | u-welder Custom | |

| 02 | Laser | According to sample welding requirements | 1 | MAX or IPG | |

| 03 | Motor | servo motor | 3 | Huichuan | |

| 04 | Computer | PC/Industrial Computer | 1 | Advantech | |

| 05 | Chiller | According to laser power | 1 | S & A | |

| 06 | Welding head | According to sample welding requirements | 1 | u-welder | |

| 07 | CCD Visual observation system | camera | 1 | Microsan | |

| light source | Basler/LeTV Light Source | ||||

| 08 | Z axis module | 300mm stroke | 1 | u-welder Custom | X, Y axis screw lead 10mm, Z axis screw

lead 5mm;screw accuracy: C7 |

| 09 | X axis module | 500mm stroke | 1 | u-welder Custom | |

| 10 | Y axis module | 300mm stroke | 1 | u-welder Custom | |

| 11 | Rotating table | Three-jaw rotary chuck | 1 | u-welder Custom | |

| 12 | Lower cabinet | Sheet metal welding, paint baking | 1 | u-welder Custom

|